Significant benefits of MIG welding

MIG welding is the simplest of the arc welding procedures for an amateur welder. MIG is among the most used joining procedures in the whole globe today. It is utilized to sign up with long metals without stopping briefly. It's the most versatile welding machine for a knowledgeable as well as professional welder regardless of your work environment - whether it's a container fabrication or auto framework building..

Its introduction remains in the California aerospace sector in the 1940s hence it has expanded its appeal. As well as likewise, its strategies appropriate for each steel specifically aluminium and magnesium. This is due to its welding speed as well as convenience of use which takes us to MIG welding benefit.

The advantages of welding are as adheres to:.

MIG is quickly.

Time taken with any type of wilding has to show the trouble of the high quality wanted from the completed weld. However, the rest of the things being equal, if MIG welding is set up versus other popular kinds of welding, MIG is mosting likely to swipe the program for a lot of the time irrespective of in whose hands it is, whether it remains in the hands of welding amateur or a seasonal fabrication. Do you understand why? The answer mainly hinges on continuously fed electrode, which could be fed from a spool weapon MIG lantern, or in a stylish industrial application or it might be fed from a welding maker via a union of push and also tablet feed technology.

Easy to use.

We will be able to figure out someday that how easy to use MIG welding is to an inexperienced beginner. One-handed accessibility on the MIG torch as well as their automation of different other facets make MIG welding straightforward to discover as well as gain proficiency with another stick welding..

Quality weld from MIG.

Quality comes for MIG welding. MIG welding helps you to make extremely premium welds very rapidly contrasted to various other welding methods. MIG is flux cost-free so slag will not get allured in the weld. MIG makes fantastic welds fast.

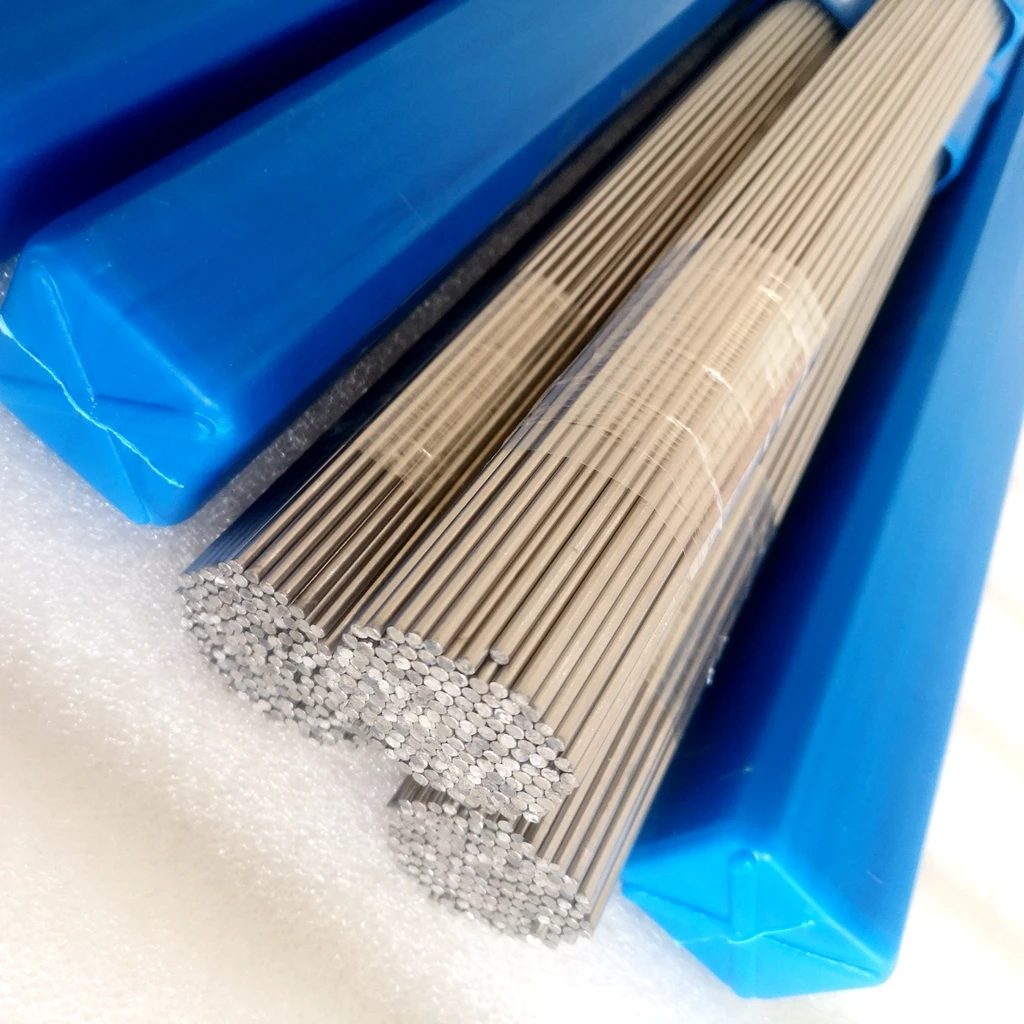

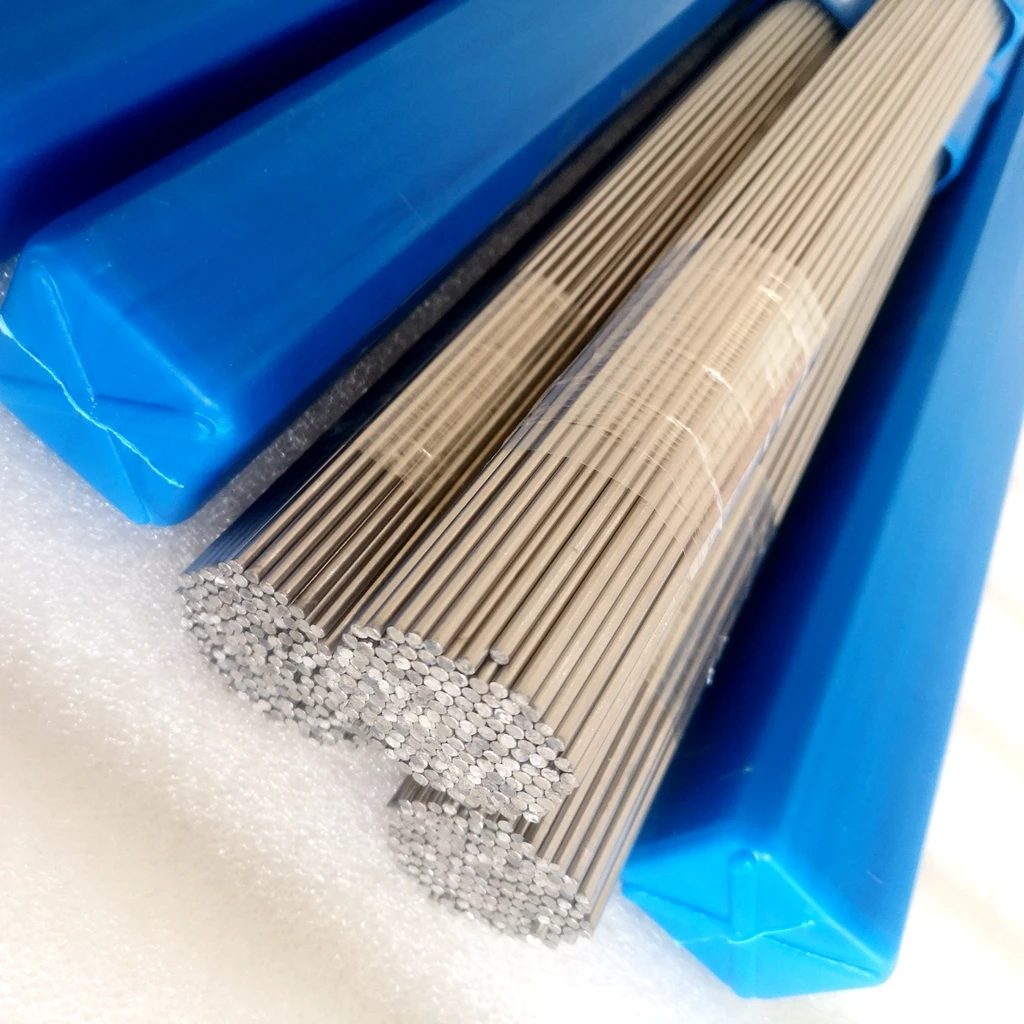

5356 aluminum MIG wire .

This is an additional reason that MIG is scoring for rate. With MIG you are transferring more weld steel with the pass of the MIG lantern. Sure, that's much less of an advantage when you are working for a tiny weld but when you are making a lengthy and complicated weld the work can be completed with less passes, which conserves a whole lot more time than other welding and helps you to work more successfully and also if it's your career then you can work extra effectively.

Infiltration matters.

Surely it does and with MIG fantastic infiltration can be anticipated. With infiltration, a solid and smooth grain can also be anticipated. Penetration here indicates deepness of your weld. The most effective component here is you can accomplish this on a wide variety of metals with various densities. Whether it is aluminium, steel or secure you don't need to fret. All you require to do is resolve the correct existing for the wire and also the metal.

MIG deals with various steels and alloys.

MIG is a functional welding maker. Hope you bear in mind exactly how it was established for magnesium and aluminium alloys, which were utilized in The golden state aircraft manufacturing facilities. This confirms MIG works with stainless steel, alloys, and aluminium.

Electrode stub loss.

It suggests more money and time saved. If you have made use of stick welding ever before you will surely recognize also you are very experienced you will end up losing countless centimetres of each welding stick. This wastage of stick is called stub loss. But weldermetals.com can banish it if you are making use of MIG welding. This is since you can make use of all continuously fed electrodes..

MIG welding is much cleaner.

Unlike one more traditional stick welding which looks unclean MIG welding is much cleaner. It's since it's flux free and so slang is not created in MIG welding..

MIG welding offers you broadband with fantastic deposition rates. It additionally offers much less post-welding cleaning as no jargon is allured. It likewise provides far better swimming pool visibility. The process is also easily automated. Products are much less squandered in this welding. It likewise requires less fluxes. Most significantly it's really easy to use also for a full novice.

With all these attributes MIG welding steals the program against an additional welding. A professional can be more profitable with MIG welding.

Its introduction remains in the California aerospace sector in the 1940s hence it has expanded its appeal. As well as likewise, its strategies appropriate for each steel specifically aluminium and magnesium. This is due to its welding speed as well as convenience of use which takes us to MIG welding benefit.

The advantages of welding are as adheres to:.

MIG is quickly.

Time taken with any type of wilding has to show the trouble of the high quality wanted from the completed weld. However, the rest of the things being equal, if MIG welding is set up versus other popular kinds of welding, MIG is mosting likely to swipe the program for a lot of the time irrespective of in whose hands it is, whether it remains in the hands of welding amateur or a seasonal fabrication. Do you understand why? The answer mainly hinges on continuously fed electrode, which could be fed from a spool weapon MIG lantern, or in a stylish industrial application or it might be fed from a welding maker via a union of push and also tablet feed technology.

Easy to use.

We will be able to figure out someday that how easy to use MIG welding is to an inexperienced beginner. One-handed accessibility on the MIG torch as well as their automation of different other facets make MIG welding straightforward to discover as well as gain proficiency with another stick welding..

Quality weld from MIG.

Quality comes for MIG welding. MIG welding helps you to make extremely premium welds very rapidly contrasted to various other welding methods. MIG is flux cost-free so slag will not get allured in the weld. MIG makes fantastic welds fast.

5356 aluminum MIG wire .

This is an additional reason that MIG is scoring for rate. With MIG you are transferring more weld steel with the pass of the MIG lantern. Sure, that's much less of an advantage when you are working for a tiny weld but when you are making a lengthy and complicated weld the work can be completed with less passes, which conserves a whole lot more time than other welding and helps you to work more successfully and also if it's your career then you can work extra effectively.

Infiltration matters.

Surely it does and with MIG fantastic infiltration can be anticipated. With infiltration, a solid and smooth grain can also be anticipated. Penetration here indicates deepness of your weld. The most effective component here is you can accomplish this on a wide variety of metals with various densities. Whether it is aluminium, steel or secure you don't need to fret. All you require to do is resolve the correct existing for the wire and also the metal.

MIG deals with various steels and alloys.

MIG is a functional welding maker. Hope you bear in mind exactly how it was established for magnesium and aluminium alloys, which were utilized in The golden state aircraft manufacturing facilities. This confirms MIG works with stainless steel, alloys, and aluminium.

Electrode stub loss.

It suggests more money and time saved. If you have made use of stick welding ever before you will surely recognize also you are very experienced you will end up losing countless centimetres of each welding stick. This wastage of stick is called stub loss. But weldermetals.com can banish it if you are making use of MIG welding. This is since you can make use of all continuously fed electrodes..

MIG welding is much cleaner.

Unlike one more traditional stick welding which looks unclean MIG welding is much cleaner. It's since it's flux free and so slang is not created in MIG welding..

MIG welding offers you broadband with fantastic deposition rates. It additionally offers much less post-welding cleaning as no jargon is allured. It likewise provides far better swimming pool visibility. The process is also easily automated. Products are much less squandered in this welding. It likewise requires less fluxes. Most significantly it's really easy to use also for a full novice.

With all these attributes MIG welding steals the program against an additional welding. A professional can be more profitable with MIG welding.

Created at 2021-07-05 04:30

Back to posts

This post has no comments - be the first one!

UNDER MAINTENANCE